Induction Motor Slot Pole Combinations

4/11/2022by admin

Induction Motor Slot Pole Combinations 3,7/5 2140 votes

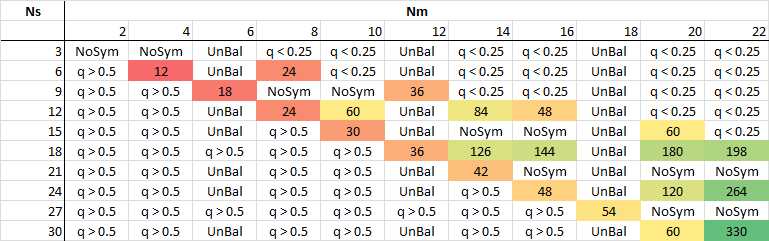

Solution: Slot per pole: 3.3 =9 For this machine design configuration, the suitable stator and pole combinations are: 18 stator slots with 2 poles 36 stator slots with 4 poles and goes on depending on your machine size. Higher pole numbers. It is possible to find high winding factors by varying the slot pitch as studied in 2 or alternatively by finding a good combination between slot and pole numbers. This second approach is more challenging because of the high number of possible combinations when the pole number is high. It is investigated in this study.

36 pole induction motor

Induction Motor Slot Pole Combinations Diagram

36 pole induction motor

Induction Motor Slot Pole Combinations List

Hi There,

I'm in the process of trying to design a 36 pole induction motor for one of our test beds in the factory. It'll be used to test a range of winches that we manufacture and by controlling this motor through a VSD we can perform certain tests without the primary gear box that gets fitted to the completed unit.

I've looked on the web at the various motor manufacturers - a motor of this size (55kW)does not exist as far as I can see, hence my efforts to design a fit for purpose motor.

Despite my best efforts, all I can achieve is a 25kW design, that runs, but with a terrible power factor (copper losses and a huge differential reaction are killing the machine).

My question (eventually) is this: is this a viable proposition in motor design? Should I be looking at a different type of motor (such as a brushless DC or similar)?

Has anybody had any experience with a motor of this size?

Best Regards

I'm in the process of trying to design a 36 pole induction motor for one of our test beds in the factory. It'll be used to test a range of winches that we manufacture and by controlling this motor through a VSD we can perform certain tests without the primary gear box that gets fitted to the completed unit.

I've looked on the web at the various motor manufacturers - a motor of this size (55kW)does not exist as far as I can see, hence my efforts to design a fit for purpose motor.

Despite my best efforts, all I can achieve is a 25kW design, that runs, but with a terrible power factor (copper losses and a huge differential reaction are killing the machine).

My question (eventually) is this: is this a viable proposition in motor design? Should I be looking at a different type of motor (such as a brushless DC or similar)?

Has anybody had any experience with a motor of this size?

Best Regards

Comments are closed.